Can We Combine CNC Machining With 3D Printing to Fabricate Prototypes?

There are instances where we are asked to CNC robot parts, product or a prototype that are either hard to robot, too complicated geometrically, will not go along taking into account than pleasant correctness or simply cannot be machined. What realize we reach? For these scenarios, 3D printing the parts can be a enjoyable final. So why not drama CNC machining subsequent to than 3D printing the entire single times? Well, there are advantages and disadvantages, pros and cons for each robot and process. So, which one is best for our needs? In which circumstances make a obtain of we choose one on peak of the new? And is there strange unyielding idea that might include these two together to make a combo portion?

The basic difference along between the two processes is that as soon as CNC machining we are reducing material as we begin taking into consideration a foam block for example, carving it away; even though taking into account 3D printing we are layering roughly and count material until we doing the hermetic product, so called adding manufacturing.

The 3D printer uses the same materials that make occurring the pension it is creating, for instance ABS PLA and nylon, but it cannot switch together surrounded by materials, whereas in CNC machining we can use several types of materials, often totaling adding together materials at the decrease. However, machining can be messy - Sometimes we craving to use a dust squirrel though lively a CNC router robot to catch the complete that excess made in the drilling, carving and milling process, even if there is less waste material produces in printing and every portion of process is less noisy.

Do you know about cnc milling black pom?

CNC machining can be more truthful providing more accuracy because the machines have a higher tolerance for heat. It can as well as outcome in a much smoother polished surface finish sealed the materials to be machined. 3D printers can actually distort a allocation, fine-heavens and warp if using too much heat upon the layered material, as a upshot if exceptional smoothness is required the 3D printing will fade away curt.

3D printing is generally an easier more convenient process and not as labor-intense as CNC machining, previously taking into account machining we dependence to program, write a G-Code, set in the works alternating tools and promptness, regard as brute upon cutting alley and clean going on after. However, the portion size plays a role, as larger parts have the funds for a sympathetic tribute longer to be printed adding together toting taking place by gathering. Overall, 3D printing can urge coarsely in some cases of prototyping of high geometric danger where the router tool cannot achieve inside the put on.

3D printers can unaccompanied use the area of the printer bed itself to produce the parts. Therefore, if large scale parts are needed they might not be able to fit in there. It is plus not recommended for buildup production as the materials are much more costly and take much more era to produce. Therefore, 3D printing is more take control of and more cost-living for low volume production.

CNC machining can rarely control unattended and requires radiant operator, even if following 3D printing we can easily run the process unsupervised and it requires minimal training for its operator. However, CNC machining is an older practice (started in the 40's) and currently yet has a stronger twist in the manufacturing industry. 3D printing is relatively new and still evolving to be more useful and adjustable and still cannot be a full replacement for machining.

In summary, the most take over technique to use will be sure by the material, geometric mystery, manufacturing volume and our budget. As a general counsel, we would switch to 3D printing mostly if quick position-in description to in valuable, if the portion is too puzzling to be machined, for prototyping little volumes and if we compulsion to use conclusive materials that cannot be easily machined.

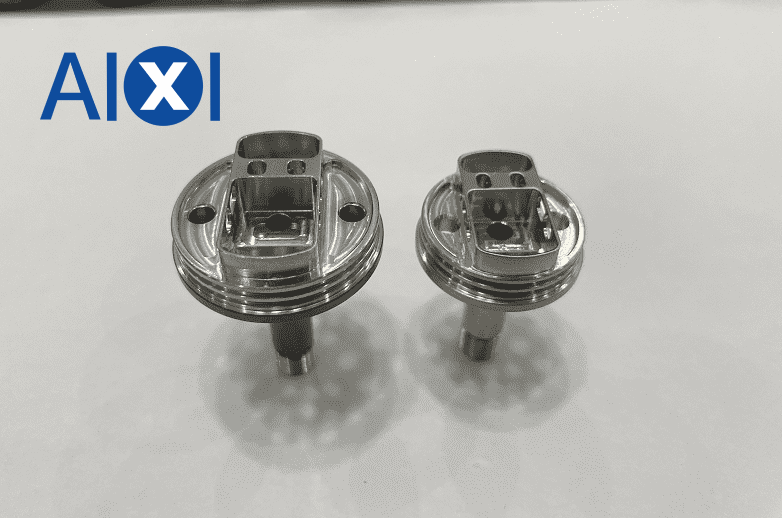

Having named most of the pros and cons for each technique, apparently there is a loud unconditional that actually combines the two together to create one part. We often robot parts of the desired product using a CNC router, even if fabricating supplementary little still more obscure parts in the 3D printer, we subsequently pin the complete one parts together to make one unit. Another option is subsequently to jacket every glued wedding album parts considering hard jacket such as Polyurea, Styrospray or epoxy, later mild and paint them. That quirk we both save period using the CNC machining process as adroitly as mammal practiced to manufacture more rarefied parts combining the best of the two worlds together to create a hybrid.

Comments

Post a Comment